Electrode Base Platform

Electrode Base Platform

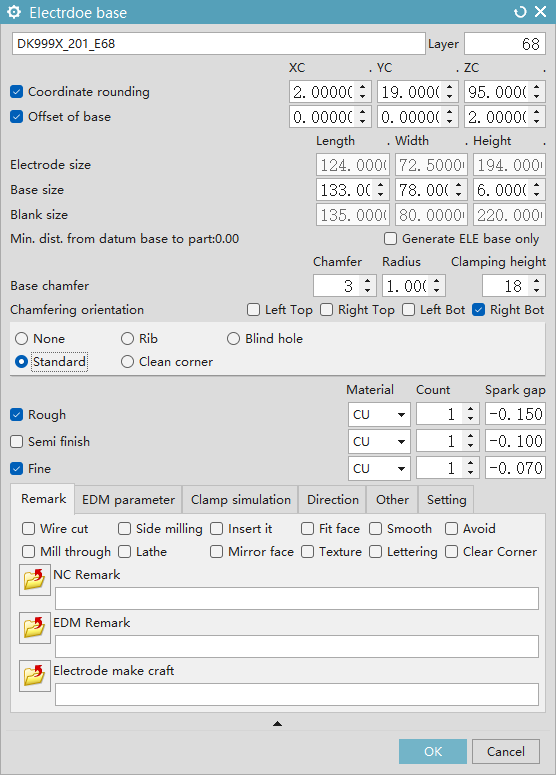

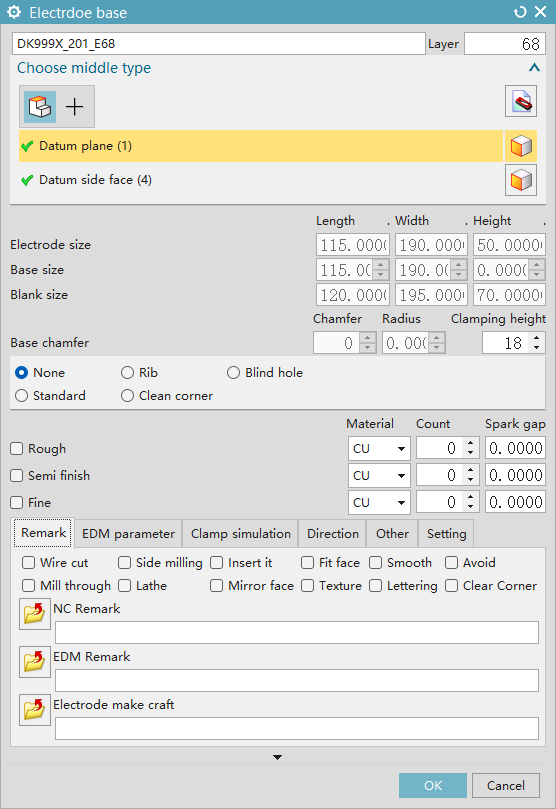

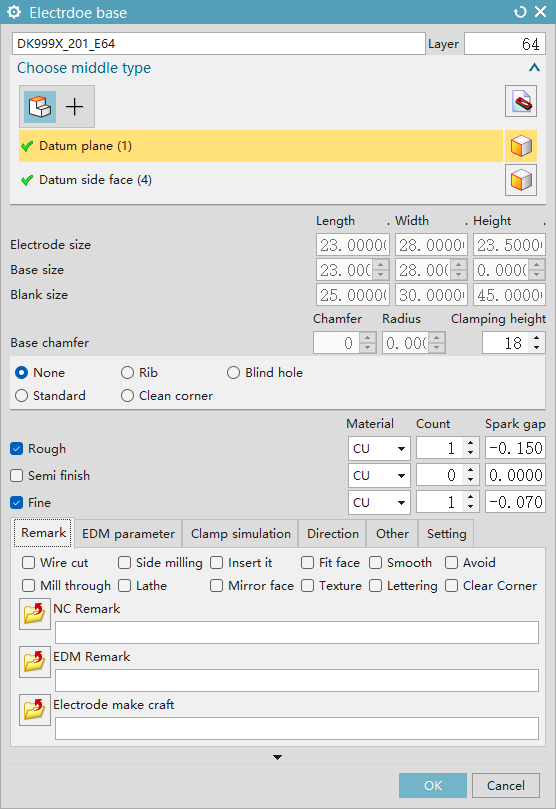

Electrode Base

- Electrode Base: Create an electrode base platform based on the electrode feature and define relevant parameters

- Electrode Number: Define the electrode number (automatically generated based on the initialized electrode number prefix)

- Layer: Define the layer number for placing the electrode (start layer is defined according to system parameter settings)

- Discharge Coordinate Rounding: Define whether to round coordinates and adjust X, Y, Z values

- Base Platform Offset: Define the offset value of the base platform; the value is inherited by the next electrode

- Electrode Dimension: Display the external dimension of the electrode head

- Base Dimension: Define the dimension of the electrode base (supports system parameters to define minimum dimension and the distance from the reference edge to the feature)

- Blank Size: Display the blank size (supports system parameters to define expansion value and increment method)

- Minimum Distance from Base Platform to Part: Display the minimum distance between the base platform and the workpiece

- Generate Base Platform Only: Generate a base platform without attributes

- Reference Chamfer/Fillet: Adjust the size of chamfer (C-angle) and fillet (supports system parameters to define default size)

- Clamping Height: Adjust the electrode clamping height (supports system parameters to define default size)

- Reference Angle Orientation: Define the direction of the reference angle (supports system parameters to define default direction or inherit the previous direction)

- None, Standard, Rib: Combine spark gaps (supports system parameters to define combinations)

- Roughing: Define the quantity, gap, and material for roughing

- Semi-Finishing: Define the quantity, gap, and material for semi-finishing

- Finishing: Define the quantity, gap, and material for finishing

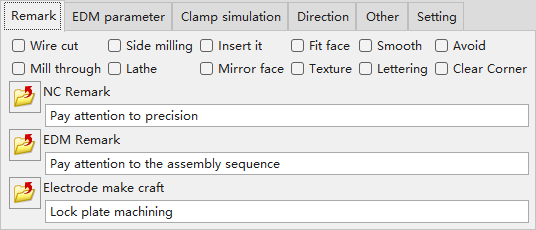

Remarks

- CNC Machining Remarks: Remarks for CNC machining precautions, used for label output (supports system parameter settings)

- EDM Discharge Remarks: Remarks for EDM discharge precautions, used for label output (supports system parameter settings)

- Electrode Process Remarks: Remarks for process information precautions, used for label output (supports system parameter settings)

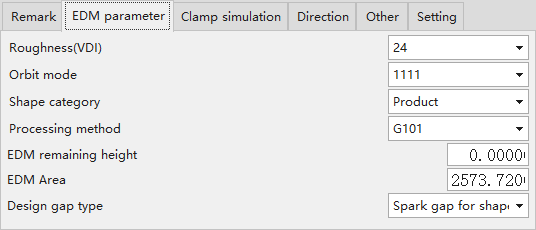

Discharge Parameters

- Surface Roughness (VDI): Define surface roughness for label output (supports system parameters to set default value)

- Oscillation Mode: Define the oscillation mode for label output (supports system parameters to set default value)

- Shape Category: Define the electrode shape for label output (supports system parameters to set default value)

- Discharge Remaining Height: Define the actual discharge height

- Projected Discharge Area: Define the projected discharge area

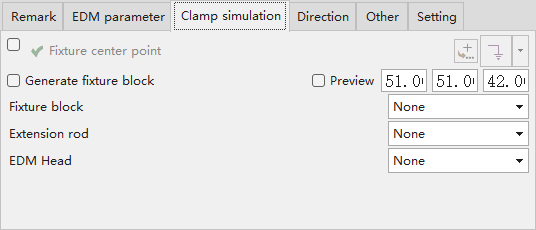

Clamping Simulation

- Fixture Center Point: Define the fixture center point (correction for original text error: not surface roughness, but fixture center * point) for label output (supports system parameters to set default value)

- Generate Fixture Block: Define the fixture center, generally used for eccentric electrodes

- Preview: View the fixture model or custom block

- Clamping Block: Select the simulated clamping block

- Extension Rod: Select the simulated extension rod

- EDM Spindle Head: Select the simulated EDM spindle head

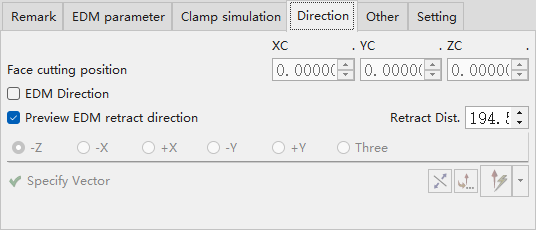

Direction

- Cutting Edge Reference Position: Adjust the 3-axis (XC, YC, ZC) linked cutting edge position

- Electrode Discharge Direction: After activating the discharge direction, it can be modified to -Z, -X, +X, -Y, +Y, Three (3-axis direction)

- Preview Discharge Retract Direction: View the electrode retract position

- Retract Distance: Set the electrode retract distance

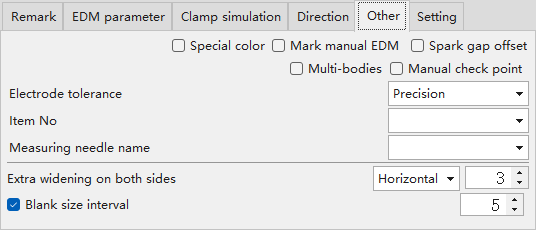

Others

- Mark Special Color: Bind a unique color ID to the electrode

- Mark Manual Discharge: After marking manual discharge, no program will be generated for scan discharge

- Mark Gap-Adjusted Body: Mark that the electrode gap has been adjusted

- Roughing-Finishing Multi-Tooth Electrode: Automatically jump to the roughing-finishing multi-tooth electrode settings

- Manual Point Acquisition: Mark that the electrode feature will not automatically acquire points

- Tolerance Type: Modify the electrode tolerance

- Material Number: Connect to the Manufacturing Execution System (MES)

- Measuring Probe Name: Specify the measuring probe to be used for the electrode

- Additional Widening on Both Sides of Base Platform: Set the corresponding direction and value for additional widening of the base platform

- Blank Size Increment Step: Set the increment value for blank size (in step units)

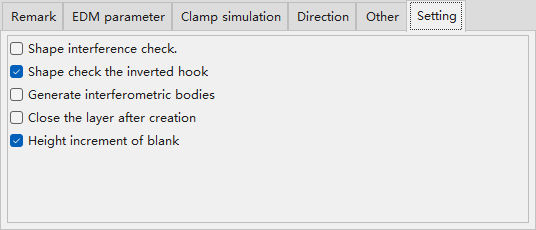

Settings

- Electrode Feature Interference Check: Check for interference between the electrode feature and the part

- Electrode Feature Undercut Surface Check: Check whether the electrode feature has an undercut surface

- Close Layer After Electrode Creation: Automatically close the electrode’s layer after the electrode is created

- Standard Blank Height Increment: Use the standard blank height increment

Special-Shaped Electrode

- Special-Shaped Electrode: Used to add attributes to special-shaped electrodes

- Select Centering Method: Choose from standard electrode, single-side reference electrode, multi-axis linkage (surface selection), lathe electrode, and square block electrode (point selection)

- Reference Plane: Define the reference plane of the electrode

- Reference Side Surface: Define the side surface of the electrode; the electrode centering method is automatically identified based on the reference side surface

Edit Special-Shaped Electrode

- Edit Special-Shaped Electrode: Modify electrodes with attributes; automatically read existing related attributes such as electrode number, gap, and quantity

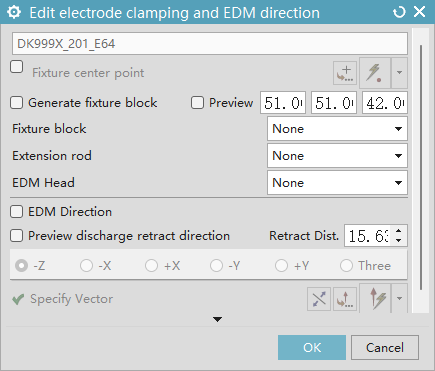

Electrode Discharge Direction

- Electrode Discharge Direction: Used to edit electrode clamping information and adjust the EDM direction

- Fixture Center Point: Define the fixture center point (correction for original text error: not surface roughness, but fixture center point) for label output (supports system parameters to set default value)

- Generate Fixture Block: Define the fixture center, generally used for eccentric electrodes

- Preview: View the fixture model or custom block

- Clamping Block: Select the simulated clamping block

- Extension Rod: Select the simulated extension rod

- EDM Spindle Head: Select the simulated EDM spindle head

- Electrode Discharge Direction: After activating the discharge direction, it can be modified to -Z, -X, +X, -Y, +Y, Three (3-axis direction)

- Preview Discharge Retract Direction: View the electrode retract position

- Retract Distance: Set the electrode retract distance

Multi-Body Electrode

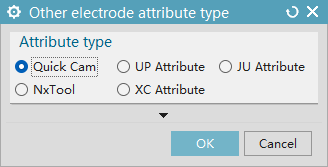

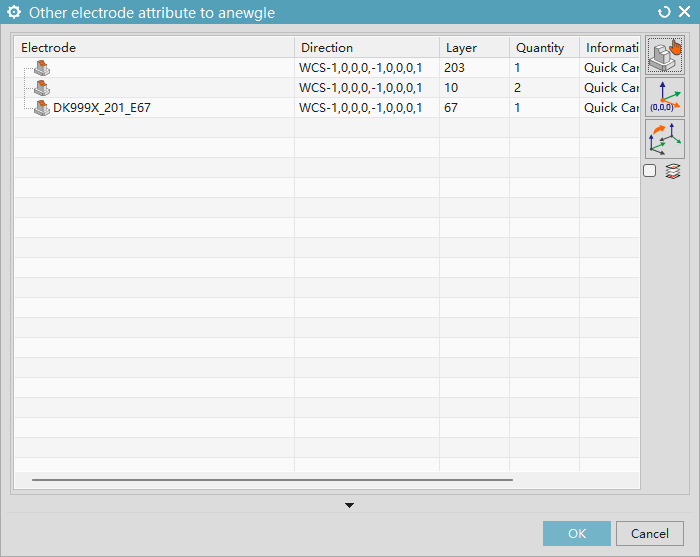

Import from Other Plugins

- Applicable to: Batch import "A Niu Attributes" (attributes from a specific plugin) from other plugins

- Select Other Electrodes: Add electrodes that need conversion

- Set WCS to Absolute Coordinate: Align the Work Coordinate System (WCS) with the absolute coordinate

- Coordinate Orientation: Specify the electrode to orient the WCS

- Close Electrode Layer After Completion: Close the electrode’s layer after the process is completed

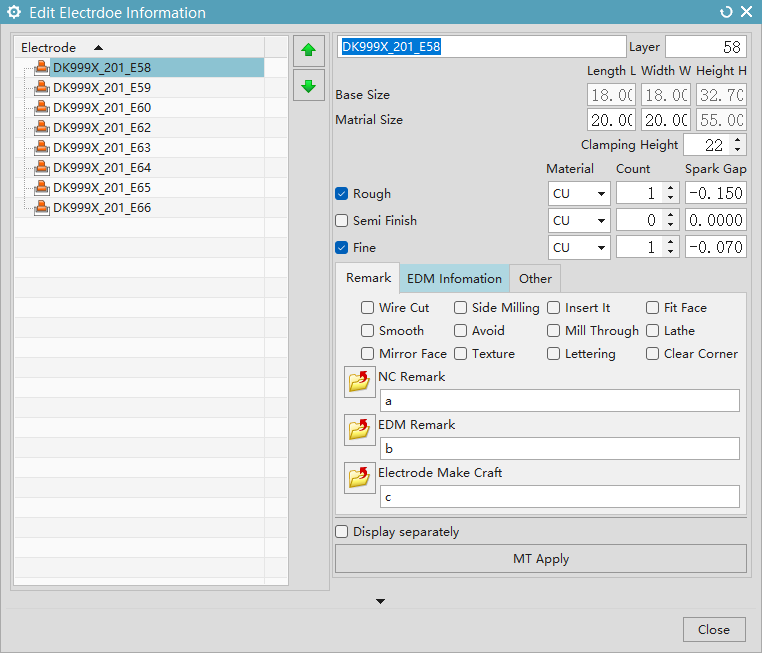

Electrode Information

- Applicable to: Editing the content of electrode information

- Display Individually: Display the selected electrode individually

- Apply: Confirm the modifications

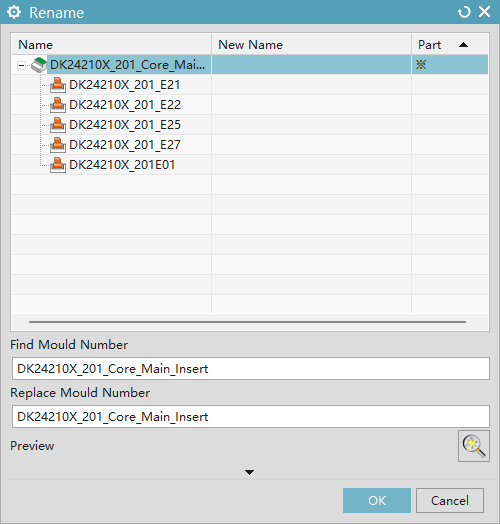

Electrode Renaming

Applicable to: When producing the same molds, batch change the electrode numbers.

- Component: Electrodes with exported Part files

- Find: String to locate electrode and mold numbers

- Replace: New string for electrode and mold numbers

- Renaming scope: Electrode attributes, electrode entity names, electrode layer names, electrode drawing names/attributes, electrode extraction drawing attributes, exported electrode Part file attributes, entity attributes/names

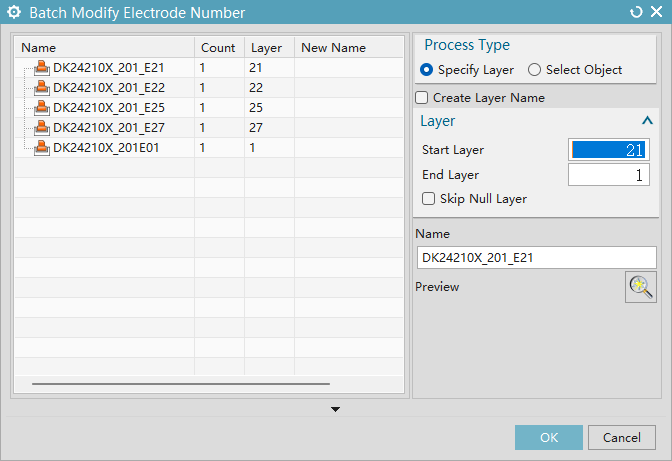

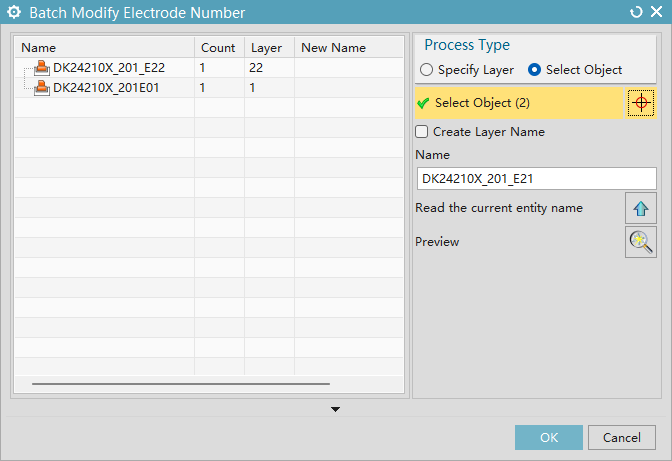

Batch Electrode Number Modification

Applicable to: Reordering after discontinuous numbering or electrode deletion

- Modification type - Specified layers: Loads all electrodes by default, renames sequentially from start to end layers with continuous incremental numbering

- Skip empty layers: Ensures consecutive electrode numbering

- Create layer name: Generates eponymous layer in electrode's parent layer

- Modification type - Selected objects: Renames chosen electrodes starting from specified name with incremental numbering, supports reading default names from selection and previewing new names

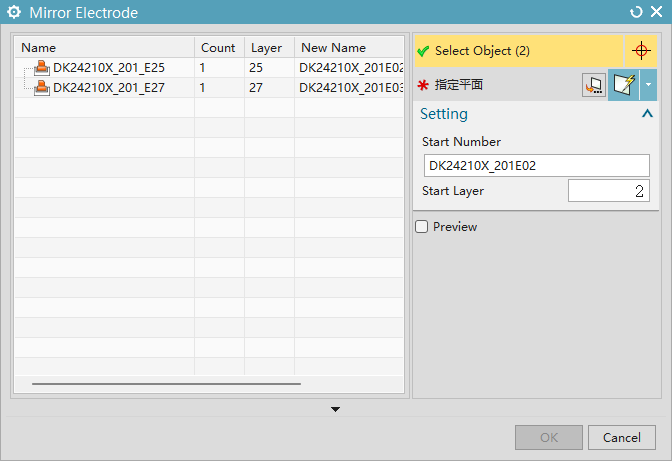

Mirror Electrodes

Applicable to: Electrode design for mirrored molds

- Select objects: Electrodes to mirror

- Specify plane: Mirror reference plane

- Start number: Initial numbering for new electrodes (auto-increments)

- Start layer: Initial layer for new electrodes (auto-increments)

- Preview: Real-time mirror effect preview